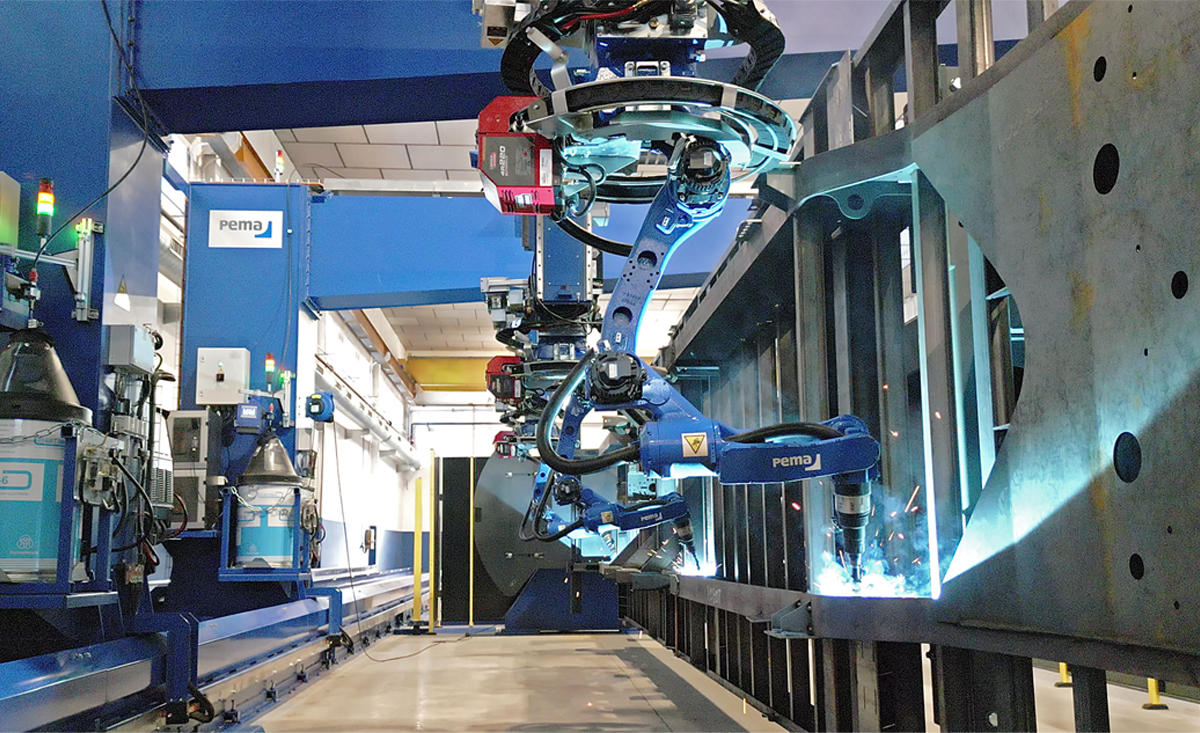

New robotic welding installation in Zaragoza: precision, speed and flexibility

Lecitrailer has set up a robotic welding installation at its factory in Zaragoza that represents a qualitative leap forward in its production processes, providing greater precision, speed and flexibility.

It is a unique system consisting of three independent columns that share the same longitudinal rail. This allows the three robotic columns to move and adapt to the different phases of the work. This flexibility allows the three robotic columns to move and adapt to the different phases of the work.

Flexibility and adaptation to all chassis

One of the main advantages of this installation is its scalable and flexible nature. The design allows for the incorporation of more robots in the future if production requires it. In addition, each station is completely identical and compatible with the others, so that the same programme can be run on any of them without the need for adjustments. This translates into greater agility in the processes and a considerable reduction in prior preparation.

The system also integrates exclusive modular tooling, developed to adapt to the diversity of chassis that Lecitrailer produces in its factory. This tooling, together with two turners that allow the parts to be rotated 360°, ensures that all welds are made in the most suitable position, achieving a finish of maximum precision and quality.

This facility reinforces Lecitrailer's commitment to continuous innovation and manufacturing excellence, consolidating the Zaragoza plant in Spain as a European benchmark in industrial automation in the trailer and semi-trailer sector.